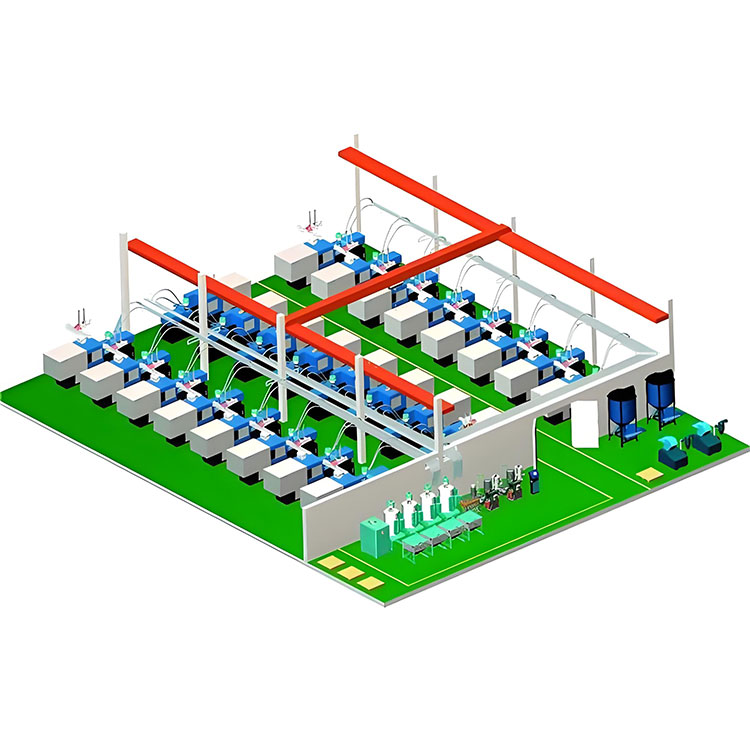

Central Feeding System

category:Centralized water supply/centralized material supply series

Details

What are the advantages of a central feeding system?

1. High efficiency: The central feeding system can automatically supply various raw materials to multiple injection molding processing equipment for use. This includes raw material drying treatment, color matching treatment, and the utilization of recycled crushed materials in proportion. It can implement highly automated control, monitoring, etc., and meet the production needs of 24-hour non-stop operation.

Second, energy conservation: The central feeding system is easy to operate. Only a few people are needed to control the feeding demand of the entire injection molding factory, thereby reducing a large amount of labor costs. Secondly, it reduces the raw material belts and corresponding auxiliary equipment beside the injection molding machine, improving the utilization rate of space. In addition, due to the adoption of the central feeding method, a large number of single machines have been reduced accordingly, thus saving electricity and reducing maintenance costs.

Iii. Personalization: The central material supply system can design the most optimized solution based on the actual production needs of different users, different workshop characteristics, and different raw material usage requirements.

Iv. Modern Factory Image The central feeding system will minimize the pollution of raw materials and dust to injection molding production, thus maintaining a clean production workshop. The unique centralized dust recovery system of the central feeding system makes cleaning more convenient, and the environmental protection effect meets the 100,000-level cleanroom operation requirements standard, and reduces noise. Ultimately, it can achieve an unmanned automated production workshop. Establish an image of modern factory management.